Manufacturing Technology

Friction Stir Welding

Car body assembly by friction stir welding (FSW)

Fig.1 Fix pin tool

Fig.2 Self-reacting pin tool

Friction Stir Welding(FSW) is adopted in assembling of aluminium carbody.

The material is not melted during this joining process. The stronger

strength and the smaller distortion due to the low heat input from

friction take the advantages to the joint design over the conventional

arc welding.

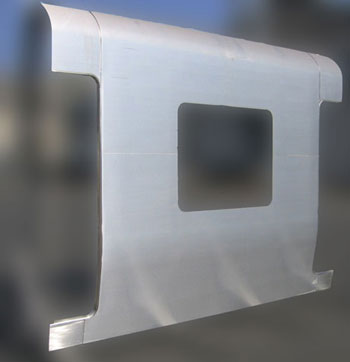

We are using the fix pin tool (Fig.1) and self-reacting pin tool

(Fig.2). Simple, strong, and lightweight for the structure are served

with this welding method.

Fig.3 FSW facility

Fig.3 shows the manufacturing facility of FSW and macro photography of the joint.

Fig.4 Numerical simulation

Fig.4 shows numerical simulation of

self-reacting pin tool.

Fig.5 Lap joint sample

Fig.5 shows the sample of the lap joint between a sheet of aluminum alloy(JIS A5083) of 2.0 mm thick and aluminum alloy extrusions(JIS A6N01) of 3.0 mm thick.

Laser Welding

Car body assembly by laser welding

Laser welding is an next generation welding method that uses high density energy laser beam. Continuous laser welding gives stainless-steel carbody structure more strength and rigidity. Laser-MIG hybrid welding runs 6 times as fast as MIG welding. It also makes stiffer and lighter structure.

stainless steel carbody panel

hollow extrusion

Sheet Forming

Forming Press

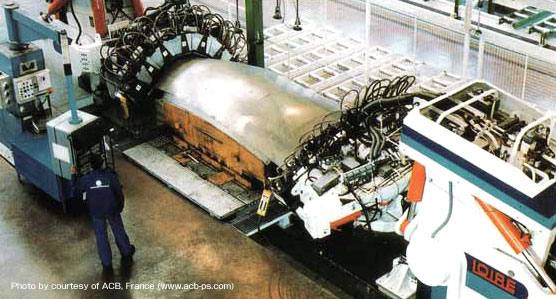

Aerodynamics require that train cars have more and more complex shape. Sheet forming is introduced in order to meet such a trend.The machine stretches the sheet, and pushes it against the shape.

Photo by courtesy of ACB, France (https://www.acb-ps.com)

Numerical Simulation Structual Analysys

Structual Analysys Fluid Analysys

Fluid Analysys Acoustic Analysys

Acoustic Analysys TestingPhototyping

| Manufacturing Technology

TestingPhototyping

| Manufacturing Technology