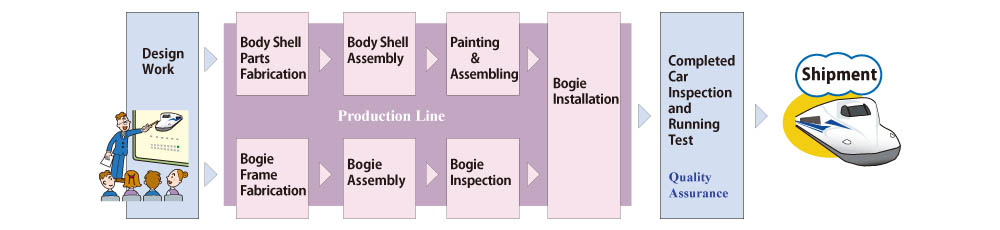

Shinkansen@Manufacturing Process

Design Work

Basic Design

Exploring basic design from the perspectives of safety,passenger comfort and high-speed performance,required for rolling stock

Detail Design

Conducting design examination, structural strength analysis,aerodynamic analysis, kinematic analysis and performance analysis to complete detailed design drawings with 3D CAD

Body Shell Parts Fabrication

Body Parts Process

Processing sheet materials into parts

Welding

Assembling each framesiunder frame, side frame, end frame, roof frame and front framejby welding.

Body Shell Assembly

Assembling each frames

Assembling each frames by welding to complete carbody shell.

Completing carbody shell

Complete carbody shell assembly by welding and transferring it by overhead crane.

Painting & Assembling

Painting

Completely assembled body shells are painted and then transferred to the outfitting line.

Outfitting

Installing underfloor components

Wiring and Piping Work

All electrical wires and air pipes are installed

Interior Work

Fitting panels, partitions, etc. to finish the interior

Bogie Frame Fabrication

Bogie Frame Welding

Welding performed by hand and by welding robots

Bogie Frame Machining

Bogie Frames are processed by automated precision machine.

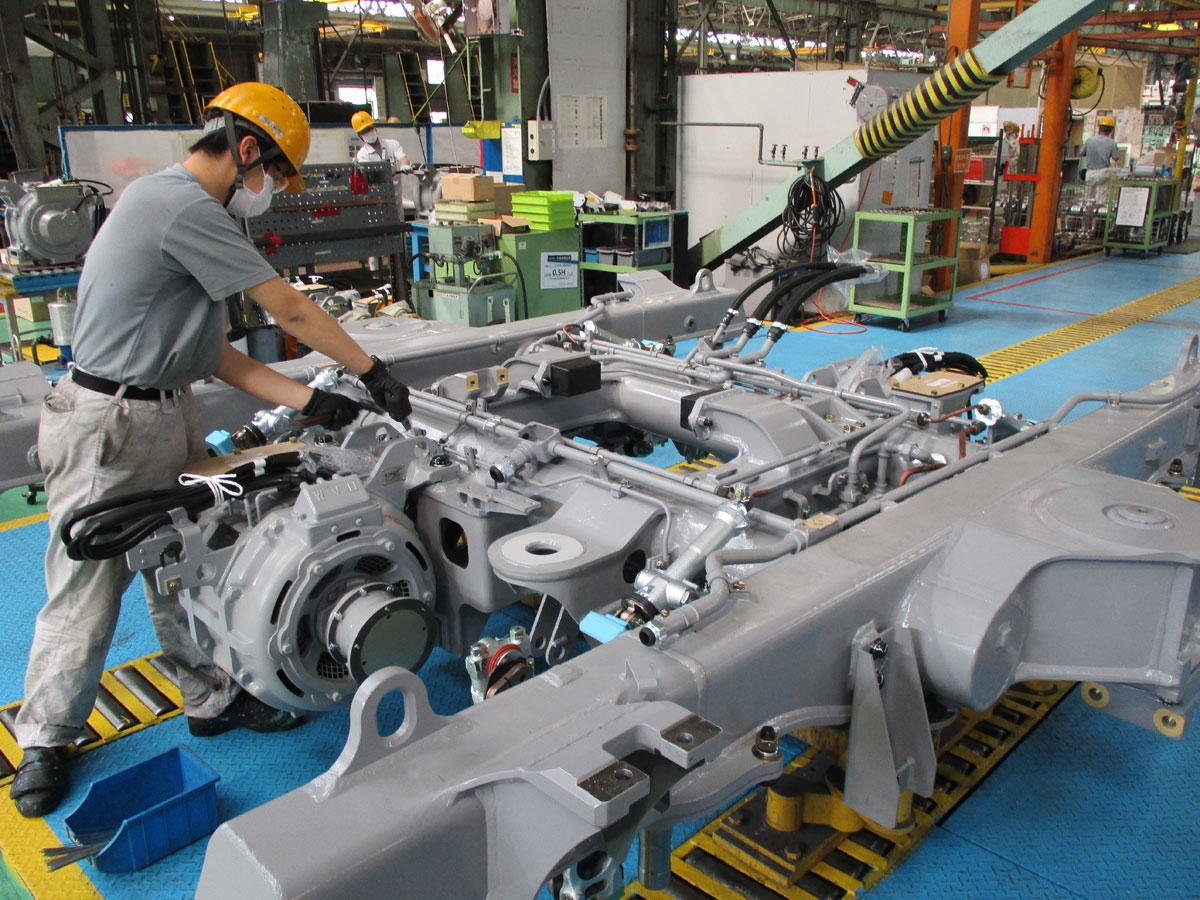

Bogie Assembly

Bogie Assembly

Installing pipes, motors, etc. onto the bogie frame

Bogie Completion

Installing wheels to complete a bogie

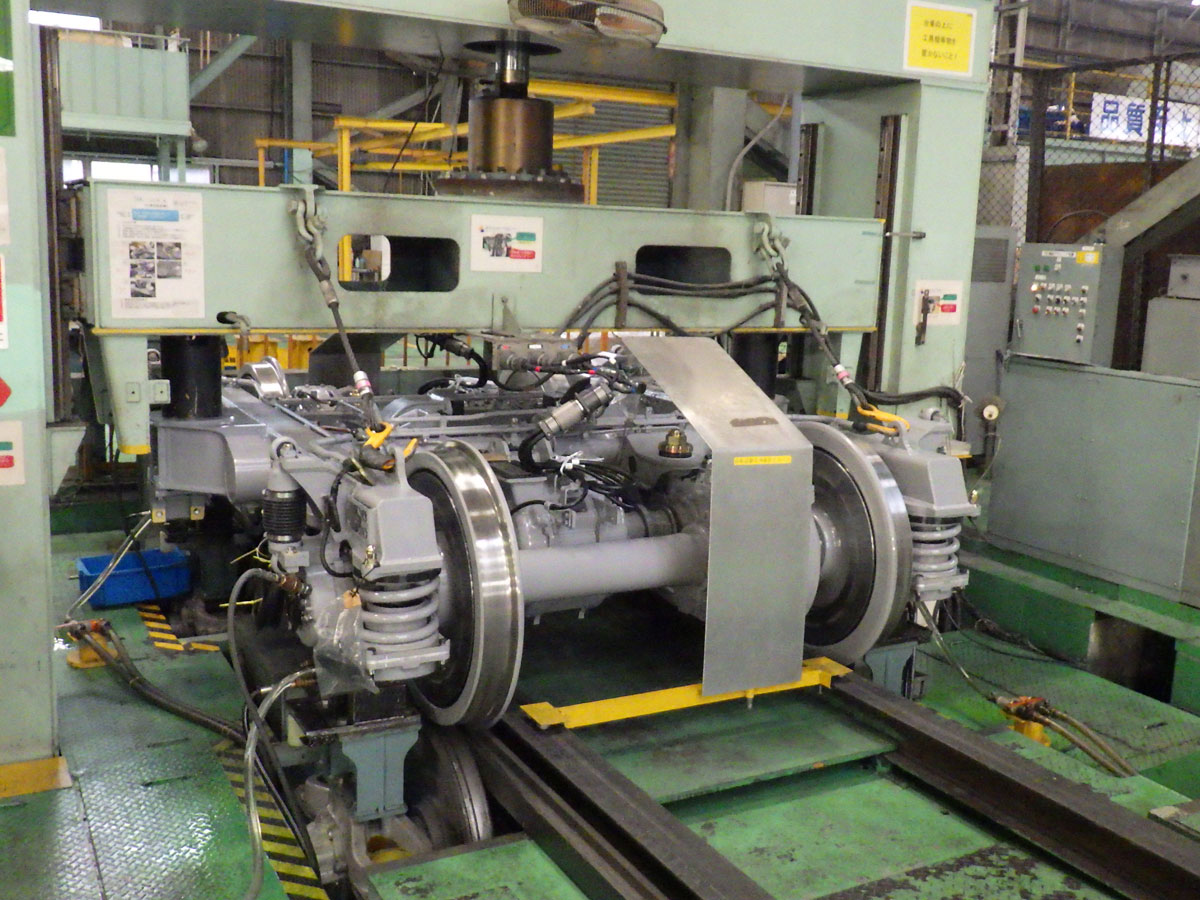

Bogie Inspection

Bogie Inspection

Load test, Rotating test etc. are performed strictly

Bogie Installation

Bogie Installation

Finally, the completed carbody is lowered onto the bogies

Completed Car Inspection and Running Test

Completed car Inspection

Car performance and workmanship are verified using various test equipment or facility

Running Test

The car performance is carefully checked with running on the test truck in the Plant

Shipment

Shipping preparation

On standby with transportation bogies fitted

Transportation

Using a trailer to transport the completed car to the railway company